Synchronous Belts

产品内容

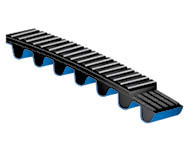

Poly Chain® GT® Carbon™ Belts

Poly Chain® GT® Carbon™ Belts

Poly Chain GT Carbon Belts — Nothing Tougher.

Give yourself a competitive advantage by designing in the Gates Poly Chain GT Carbon drive system instead of roller chain in your next power transmission application.

The patented use of Carbon Fiber as the tensile cord provides increased horsepower rating for greater power density and compactness and increased flexibility, allowing the use of backside idlers. When combined with Gates Poly Chain GT2 sprockets, you have a lightweight, long-lasting, maintenance-free system that’s more than a match for roller chain.

Features/Advantages

Maintenance-free, clean solution for roller chain drive conversion

Significantly reduces maintenance costs

Equivalent capacity to roller chain drives in the same width

Easy rust-free wash-down with Gates Stainless Steel hardware

Fast drive conversion payback

Quieter than roller chain drives

Robust carbon tensile cord combines minimal stretch with extraordinary strength and load carrying capacity, while absorbing shock and surge loads.

Durable polyurethane construction resists chemicals, oil, pollutants, and abrasion.

Nylon tooth facing reduces friction and eliminates the need for lubrication.

Fully operational in temperature extremes of -65°F to +185°F (-54°C to +85°C).

Available in the following pitches: 5 mm, 8 mm, 14 mm.

Also available in Long Length belting well suited for linear movement, positioning and conveying applications.

Poly Chain® Carbon™ Volt™

Poly Chain® Carbon™ Volt™

THE POWER YOU WANT

THE SAFETY YOU NEVER HAD.

Poly Chain® Carbon™ Volt™ belts deliver unmatched antistatic performance

Antistatic power transmission belts are a must in volatile environments. Power transmission belts that meet the ISO 9563 standard for static conductivity are only required to meet that level when new. As soon as the belts are in use, their antistatic properties decrease – dramatically.

Now you have a safer – and stronger – option. Gates Poly Chain Carbon Volt belts deliver the power and performance you expect only from a Gates Poly Chain belt system, as well as an industry-leading reliable dissipation of electrostatic charges.

Poly Chain Carbon Volt belts meet ISO 9563 standards from start to finish.

Download the flyer

Poly Chain Carbon Volt construction is available in all Poly Chain Carbon GT sizes. Common sizes are made to stock, check with customer service.

PowerGrip® GT®3 Belts

PowerGrip® GT®3 Belts - 2M and 3M

The PowerGrip GT3 belt has twice the load carrying capacity of its predecessor HTD®. In addition, less width is required compared to HTD, allowing lighter, more compact drives.

Markets/Applications

PowerGrip GT3 belts are suitable for many applications including data storage, machine tool, hand power tools, postage handling, DC Stepper/Servo, food processors, office machines, centrifuges, money handling, medical diagnostic, sewing machines, ticket dispensers, robotics, vending machines and vacuum cleaners.

Features/Advantages

Fiberglass tensile cord provides high strength, excellent flex life, and high resistance to elongation.

Neoprene body provides protection against grime, grease, oil, and moisture.

Nylon tooth facing provides a durable wear surface for long service life.

Gates patented tooth profile is designed for use with a specific sprocket groove profile. The sprocket groove-belt tooth combination increases capacity, while improving registration.

PowerGrip GT3 greatly exceeds HTD in tooth ratchet resistance.

Eliminates lubrication and re-tensioning reduce maintenance and labor as compared to roller chain drives.

PowerGrip GT3 belt sprocket combinations match or exceed the positional accuracy of PowerGrip Timing belt/pulley systems.

Recommended Sprockets

PowerGrip® GT®2 Sprockets

Notes

PowerGrip GT3 part numbers are comprised of pitch, pitch length and width. For example; part number 100-2MGT-04 denotes a 2mm pitch, 100mm pitch length and 4mm width.

Belt pitch is the distance in millimeters between two adjacent tooth centers as measured on the pitch line of the belt. Belt pitch length is the total length (circumference) in millimeters as measured along the pitch line. The theoretical pitch line of a PowerGrip GT3 belt lies within the tensile member.